Materials Engineering

The research topics of Materials Engineering Research Group are highly associated with the advancement of material properties and functionality, with the consideration of implementing clean and sustainable technology. Furthermore, our interest area expands in wide range, from fundamental- to application-based studies. Our main research fields are related, but not limited to materials science technology, tribology, and additive manufacturing.

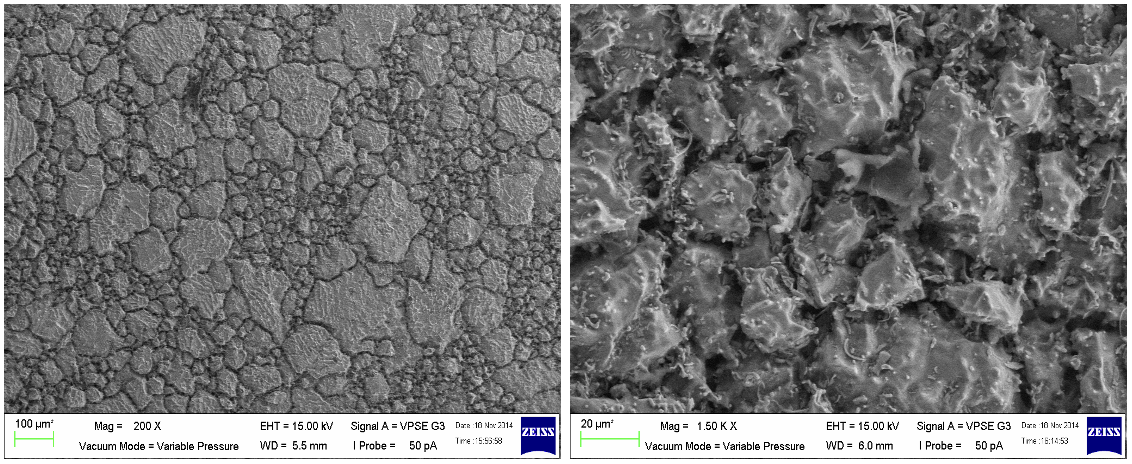

One of our recent research works includes microstructure characterization, and study of the mechanical and tribological properties of carburized steel and various types of coatings at elevated temperature. We are also investigating the effectiveness of MQL (Minimum Quantity Lubrication) utilizing various types of environmentally friendly fluids in machining stainless steel with various combinations of tool substrates and coatings.

Thermoformable 3D printed multi-material

In the research related to additive manufacturing field, 3D printing of functional parts, utilization of waste plastics as 3D printer material, and tribological characteristics of 3D printer material are actively being investigated. Additionally, modelling and simulation of metal additive manufacturing processes using laser and electron beam, and development of applications using fused filament are also being studied.

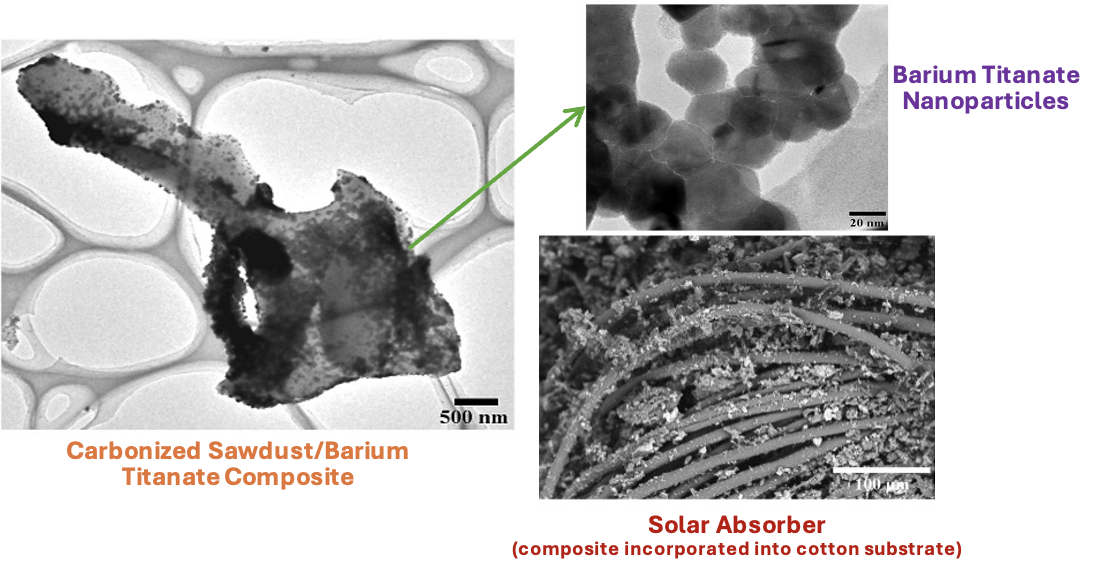

In consideration of green technology, various waste materials are converted into functional carbon materials by exploiting numerous methods (pyrolysis, hydrothermal, etc.). Recently, the carbon materials derived from waste biomass are being used as the photothermal conversion materials for solar vapor generation, generating clean water by utilizing renewable solar energy. Some of the carbon materials are integrated with nanoparticles to produce nanocomposites, in order to further enhance their performance.

SEM images of the surfaces of the mild steel carburized for 3 hours

Leader: Assoc. Prof. Ir. Ts. Dr. Melvin Gan Jet Hong

Expertise: Carbon Materials, Nanomaterials, Composite Materials

Focus:

- Conversion of waste materials into functional carbon materials.

- Solar vapor generation for clean water production.

- Surface functionalization, heat treatment, material characterizations.

Selected Publications:

- Hydrothermally derived hydrochar from waste sawdust for solar vapor generation, DOI: 10.1002/ente.202400367

- Carbonized sawdust based solar absorber in a solar still for seawater desalination, DOI: 10.1002/ep.14449

- Interfacial solar vapor generation using sawdust hydrochar/titanium dioxide composite as photothermal conversion material, DOI: 10.1007/s41779-024-01063-1

- Carbonized sawdust/barium titanate composite solar absorber for solar driven seawater desalination, DOI: 10.1016/j.ceramint.2021.12.198

- Facile mild hydrothermal treatment for surface functionalization of carbonized sawdust, DOI: 10.1016/j.matchemphys.2021.124371

- Wear processes and performance of blade pair in small‐scale single‐shaft plastic shredder machine, DOI: 10.1002/mawe.202200270

- Post-heat treatment of electrochemically carburized low-carbon steel, DOI: 10.5599/jese.1638

- Surface functionalization of vertical graphene significantly enhances the energy storage capability for symmetric supercapacitors, DOI: 10.1016/j.carbon.2023.118511

- Plasma-induced N doping and carbon vacancies in self-supporting 3C-SiC photoanode for efficient photoelectrochemical water oxidation, DOI: 10.1039/D4TA02612H

- Hierarchically structured electrode materials derived from metal-organic framework/vertical graphene composite for high-performance flexible asymmetric supercapacitors, DOI: 10.1016/j.est.2023.108055

- Large-scale vertical graphene on nickel foil as a binder-free electrode for high performance battery-like supercapacitor with an aqueous redox electrolyte, DOI: 10.1016/j.jpowsour.2023.233183

Intellectual Property: Copyright, “Configuration of Blades for Small-scale PET Shredder Machine”, LY2022S06607, MyIPO (2023).

Member: Prof. Ir. Dr. Willey Liew Yun Hsien

Expertise: Tribology, Surface Engineering, Machining

Focus:

- Tribology, especially wear of carburized steel and coatings in sliding.

- Effect of lubrication on the machinability of various materials using coated carbide tools.

- Thermal effect on the oxide formation, microstructure and mechanical properties of coatings.

Selected Publications:

- A systematic investigation of the tribological behaviour of oxides formed on AlSiTiN, CrAlTiN, and CrAlSiTiN coatings, DOI: 10.1016/j.wear.2022.204552

- Thermal stability, mechanical properties, and tribological performance of TiAlXN coatings: understanding the effects of alloying additions, DOI: 10.1016/j.jmrt.2022.01.005

- A short review on the phase structures, oxidation kinetics, and mechanical properties of complex Ti-Al alloys, DOI: 10.3390/ma14071677

- Effect of Co on solidification characteristics and microstructural transformation of nonequilibrium solidified Cu-Ni alloys, DOI: 10.1007/s11595-024-2900-z

- Application of modified kaolinite in improving thermal stability of polydimethylsiloxane, DOI: 10.1002/vjch.202300183

- High temperature (up to 1200°C) thermal-mechanical stability of Si and Ni doped CrN framework coatings, DOI: 10.1016/j.jmrt.2021.07.130

- Reciprocating wear behavior of mild steel carburized using Na2CO3-NaCl, DOI: 10.1016/j.triboint.2015.11.040

- Sliding wear of electro-carburized mild steel with different microstructures, DOI: 10.1080/17515831.2020.1838099

- Evolution mechanism of rapid solidification microstructure of an undercooled copper-based single phase alloy, DOI: 10.1016/j.jmrt.2024.06.130

- Thermal characterization of binary calcium-lithium chloride salts for thermal energy storage at high temperature, DOI: 10.3390/en16124715

- A binary salt mixture LiCl–LiOH for thermal energy storage, DOI: 10.3390/ma16041434

- Monatomic reactions with single vacancy monolayer h-BN: DFT studies, DOI: 10.1039/D3RA05108K

- Enhancement of thermal and mechanical stabilities of silicon doped titanium nitride coating by manipulation of sputtering conditions, DOI: 10.1016/j.jmrt.2022.01.039

Member: Ir. Dr. Chua Bih Lii

Expertise: Metal Additive Manufacturing, Material Extrusion, Finite Element

Focus:

- Multi-material for integrated and efficient additive manufacturing product.

- Effect of additives and impurities in filament on tribological properties.

- Thermal-metallurgical-mechanical analysis for metal additive manufacturing process.

Selected Publications:

- Thermoforming characteristics of PLA/TPU multi-material specimens fabricated with fused deposition modelling under different temperatures, DOI: 10.3390/polym14204304

- Numerical investigation of deposition characteristics of PLA on an ABS plate using a material extrusion process, DOI: 10.3390/ma14123404

- Estimation method of interpass time for the control of temperature during a directed energy deposition process of a Ti–6Al–4V planar layer, DOI: 10.3390/ma13214935

- Estimation of appropriate process parameters for a plasma electron beam re-melting process using finite element analysis, DOI: 10.7736/JKSPE.019.102

- Influences of deposition strategies on thermo-mechanical characteristics of a multilayer part deposited by a wire feeding type DED process, DOI: 10.1007/s12206-019-1102-7

- A study on activation algorithm of finite elements for three-dimensional transient heat transfer analysis of directed energy deposition process, DOI: 10.1007/s12541-019-00118-9

- Influence of process parameters on temperature and residual stress distributions of the deposited part by a Ti-6Al-4V wire feeding type direct energy deposition process, DOI: 10.1007/s12206-018-1035-6

- Influence of angle of corner deposition on temperature and residual stress distributions in the vicinity of the deposited region by a Ti-6Al-4V wire-feeding type of direct energy deposition process, DOI: 10.7736/KSPE.2018.35.9.853

- Estimation of effective thermal conductivity of Ti-6Al-4V powders for a powder bed fusion process using finite element analysis, DOI: 10.1007/s12541-018-0030-2

- Investigation of penetration depth and efficiency of applied heat flux in a directed energy deposition process with feeding of Ti-6Al-4V wires, DOI: 10.7736/KSPE.2018.35.2.211

- Influence of corrugation angle and load position on the flexural characteristics of lightweight plastic sandwich panel with corrugated cores, DOI: 10.7736/KSPE.2017.34.7.493

Collaborators:

- Jiangxi Normal University, China

- Shinshu University, Japan

- Murdoch University, Australia

- United Arab Emirates University, United Arab Emirates

- Purdue University, USA

- Huanghe Jiaotong University, China

- Chosun University, Korea

Barium titanate nanoparticles attached onto the surface of carbonized sawdust to form composite materials